In recent years, the growing problem of electronic waste, or E-Waste, has emerged as a significant challenge for the electronics industry. With rapid technological advancements and the increasing demand for electronic devices, E-Waste has become one of the fastest-growing waste streams globally. Manufacturers play a vital role in the generation and disposal of E-Waste, so they must explore sustainable design and production practices to minimize its negative impact on the environment and society.

This blog post will explore the key strategies and measures electronics manufacturers can adopt to reduce E-Waste generation throughout a product’s lifecycle. We will discuss the importance of eco-friendly design, material selection, production processes, and end-of-life considerations for electronic products and components. Furthermore, we will highlight the benefits of partnering with a responsible E-Waste recycling provider like ReWorx Recycling, which offers comprehensive services such as Global IT Asset Disposition, E-Waste Recycling, and more.

Sustainable Design Principles for Electronics Manufacturers

To meaningfully reduce E-Waste, electronics manufacturers must incorporate sustainable design principles throughout product development. Consider the following points for designing environmentally friendly electronic devices:

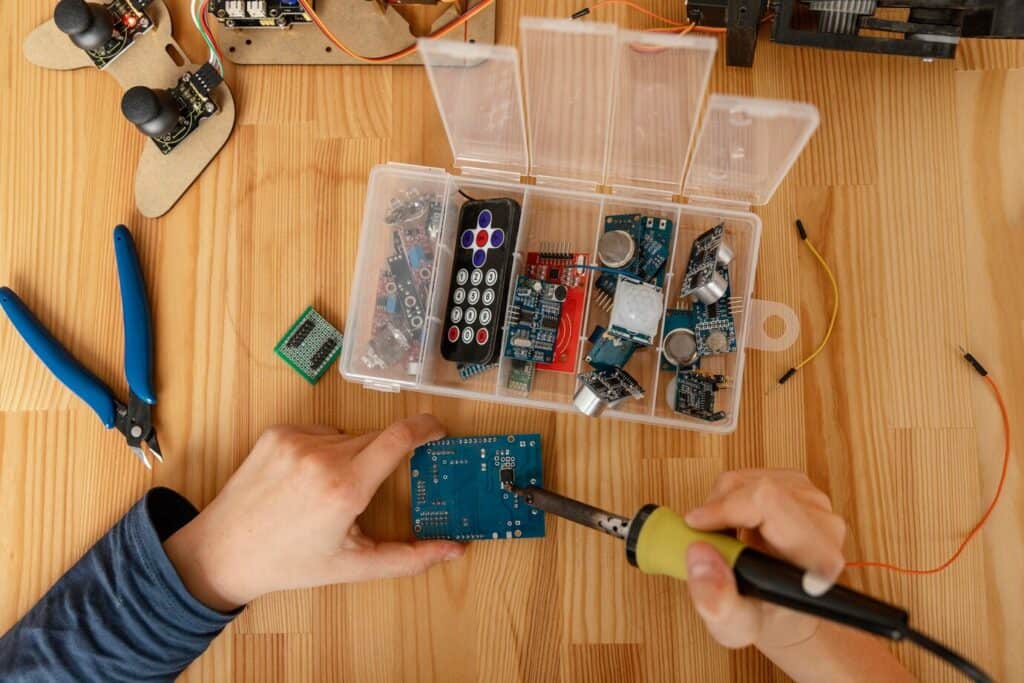

1. Modularity: Design products to be modular, allowing users to replace or upgrade components instead of disposing of the entire device. This approach prolongs the lifespan of devices and reduces waste.

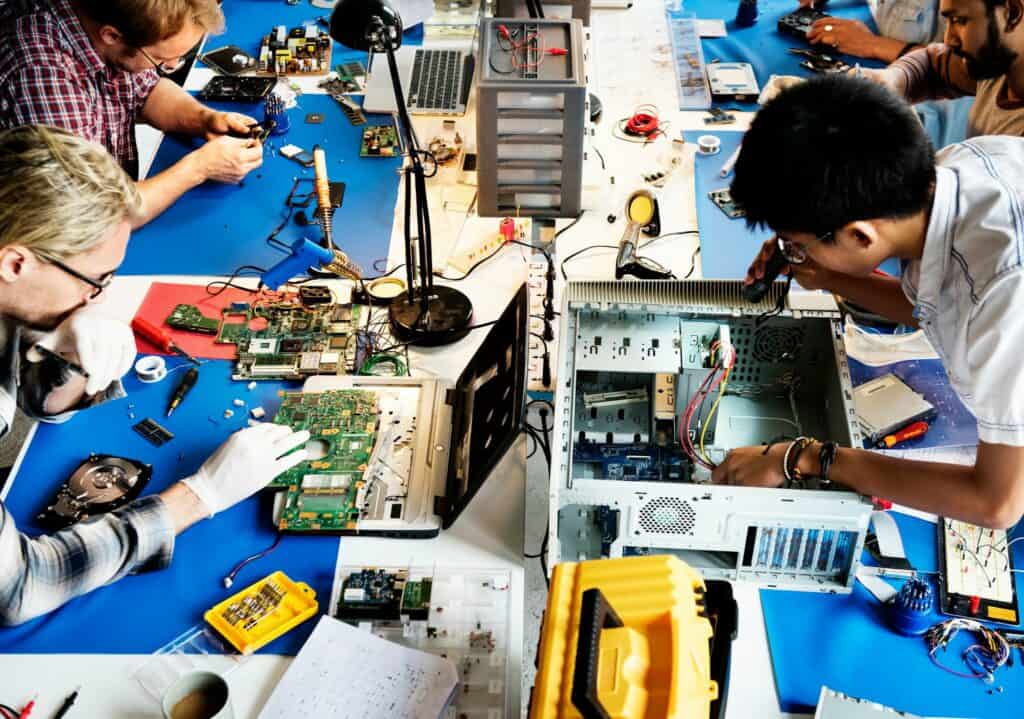

2. Ease of repair: Build devices with repairability in mind, making it simple for users or repair technicians to replace malfunctioning components.

3. Energy efficiency: Develop energy-efficient products by selecting components that consume minimal power and designing power management systems that optimize energy use.

4. Material selection: Choose materials with lower environmental impacts, considering factors such as recyclability, biodegradability, and low toxicity.

5. Life cycle assessment: Perform a life cycle assessment (LCA) of the product to evaluate its environmental impact during the design and development process. This information can guide the selection of materials, components, and manufacturing processes that minimize negative effects.

Environmentally Friendly Manufacturing Processes

Implementing eco-responsible manufacturing processes is equally crucial for reducing E-Waste. Manufacturers should embrace the following practices:

1. Lean production: Optimize production processes to minimize waste, save energy, and reduce raw material consumption. Lean production methods promote efficiency and reduce the environmental footprint of any manufacturing process.

2. Green supply chain management: Collaborate with suppliers who share a commitment to sustainability and follow eco-friendly practices for sourcing materials, minimizing hazardous substances, and effectively managing waste.

3. Resource-efficient manufacturing: Embrace manufacturing technologies and processes that conserve water, reduce energy consumption, and optimize resource utilization.

End-of-Life Considerations and Recycling Partnership

End-of-life considerations are an essential aspect of combating E-Waste. Electronics manufacturers must take proactive steps to ensure products are disposed of and recycled responsibly:

1. Take-back programs: Implement take-back programs that encourage consumers to return used devices for recycling or proper disposal. By offering trade-in options or recycling incentives, manufacturers can obtain a steady stream of devices that can be refurbished, repurposed, or efficiently recycled.

2. Educate consumers: Educate customers on the importance of proper disposal and recycling practices, providing them with user guides and online resources. This effort can help to minimize E-Waste and encourage consumers to be more environmentally conscious.

3. Recycling partnership: Collaborate with a responsible E-Waste recycling provider like ReWorx Recycling, which offers various services such as E-Waste Recycling, Secure Data Destruction, Hard Drive Shredding, Equipment Destruction, and Reverse Logistics.

The Benefits of Reducing E-Waste for Electronics Manufacturers

By committing to sustainable design and manufacturing practices, electronics manufacturers can reap numerous benefits, both commercially and environmentally:

1. Regulatory compliance: Adherence to sustainable design and manufacturing practices enables manufacturers to meet current and emerging environmental regulations and avoid potential penalties.

2. Enhanced brand reputation: As sustainability becomes an increasingly important consideration for consumers, embracing eco-friendly practices can bolster brand reputation and promote goodwill with customers and stakeholders.

3. Resource optimization and cost reduction: Sustainable design and production methods often lead to decreased resource consumption and waste reduction, resulting in cost savings throughout the product life cycle.

4. Increased market appeal: As the demand for sustainably and ethically produced electronics grows, products designed with environmental responsibility can attract a wider customer base and offer a competitive advantage in the marketplace.

Pioneering a Sustainable Future Through Eco-Innovation

Electronics manufacturers can profoundly contribute to a more sustainable future by committing to responsible design, manufacturing, and disposal practices. Minimizing E-Waste through eco-innovation offers immense potential for environmental conservation and commercial success, fostering a balanced and forward-looking approach to electronics production.

Take the first step towards embracing sustainable design and manufacturing today by consulting with ReWorx Recycling for expert insight and guidance on reducing E-Waste and adopting environmentally responsible disposal solutions for electronic devices. Enjoy our E-Waste recycling services today.